ENTHALPY HEAT WHEELS

Harness the Power of Air: Advanced Energy Recovery for a Sustainable Future

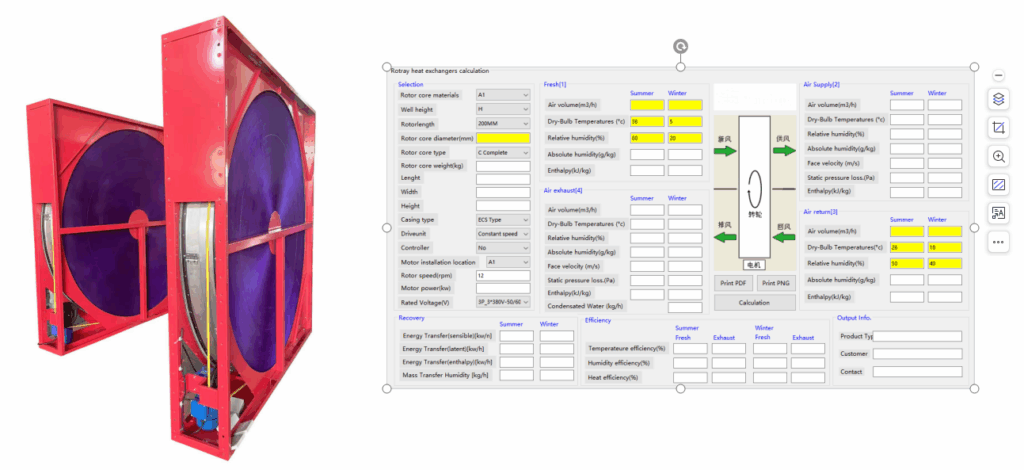

In the face of a global energy crisis, innovation in efficiency is no longer a luxury—it is an imperative. At the forefront of this movement, energy recovery ventilation has emerged as a critical and intelligent solution for modern buildings. This technology is transforming the ventilation industry, becoming a standard feature in high-performance central air conditioning units and fresh air ventilators.

The principle is one of elegant efficiency. Instead of expelling stale indoor air and wasting the energy used to condition it, our systems capture that valuable energy. Advanced heat recovery cores act as a vital exchange point between two opposing air streams: the outgoing exhaust air and the incoming fresh air.

In winter, the system recovers heat from the warm, exhausted air and uses it to pre-warm the cold, incoming fresh air. In summer, the process reverses, transferring heat from the hot outside air to the cooler exhaust air, thereby pre-cooling the incoming supply. This process not only manages temperature (sensible energy) but also humidity (latent energy), transferring water molecules to maintain ideal comfort levels without extra energy expenditure.

The benefits are profound. By significantly preconditioning the fresh air, the primary heating and cooling systems are drastically reduced in their workload. This translates directly to substantial reductions in energy consumption, lower utility costs, and a minimized carbon footprint. It’s a powerful step toward achieving sustainability goals and future-proofing your operations against rising energy prices.

Embrace a smarter, more sustainable approach to indoor climate control. Our energy recovery systems are not just a product; they are a long-term investment in operational efficiency, environmental responsibility, and unparalleled indoor air quality.

DESICCANT HEAT WHEELS

Desiccant Wheels: Precision Dehumidification & Energy Recovery

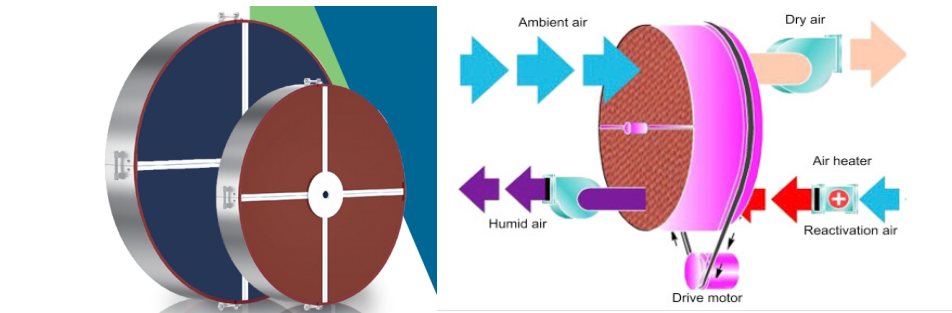

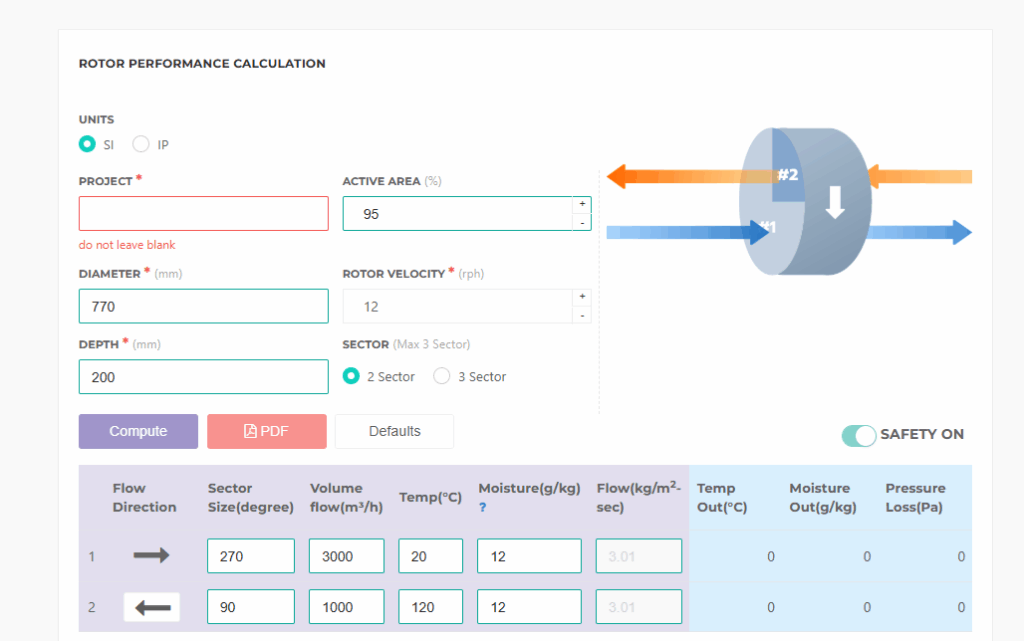

A desiccant wheel is a rotary dehumidifier that uses a solid desiccant material to actively control humidity. As the wheel rotates, it continuously cycles between two air streams: one process air stream is dried, while a separate regeneration air stream rejuvenates the desiccant.

There are two primary types to meet different needs:

· Active Desiccant Wheels: Equipped with a heater for the regeneration air, these systems provide powerful, independent dehumidification. They are ideal for industrial applications and environments requiring very low humidity levels.

· Passive Wheels (Enthalpy Wheels): Without a heater, these wheels excel at energy recovery. They transfer heat and moisture between incoming fresh air and exhaust air, significantly boosting HVAC efficiency and reducing operational costs.

Housed in a sealed, insulated unit, our desiccant wheels offer reliable, maintenance-free performance for precise climate control.

Discover the right solution for your application.